All of our products are inspected at a sampling ratio higher than 2%, which is complied to the standard of major Class Society. The inspection is mainly consisted of 4 steps, including raw material inspection, routing inspection, finished product batch test, and ex-factory inspection.

Raw material inspection

Inspecting the incoming material quality is the primary step of QC. The purpose is to eliminate quality problems from the essential period.

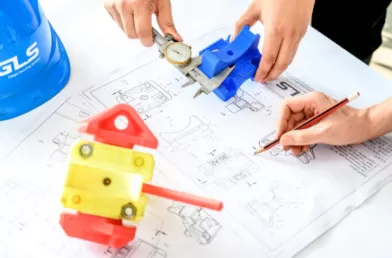

Routing inspection

Professional quality inspectors conduct regular inspections to check the production site, even to prevent quality problems in the production process.

Finished product batch test

In order to ensure that the qualified rate of finished products reaches more than 99.8%, batch inspection and testing are carried out on the finished products.

Ex-factory inspection

Qualified products that have passed the batch inspection will undergo final inspection before they leave the factory for packing to prevent product defects.

Product Design

Spectral Analysis

Thickness Measurement

Routing Inspection

Type Approval Certificates